Vertical machining center, also known as vertical milling machine, machines holes on a flat surface. VMC technology is recommended when three-axis work is done in one location, such as in die and mold work. VMC can be modified in many ways. There are countless tools, for example, angle approximation, rotation of the work area, etc. Integrated computer controls enable automation, repeatability, tool selection/changeover and contour control. This new CNC machine tool increased the productivity of “milling” machine tools to unprecedented heights, giving rise to the term VMC (Vertical Machining Center).Vertical machining centers can produce parts and components for a variety of industries and applications. These are mainly used in high-precision, high-accuracy, and large-scale applications

Complex curves are found in places like cams, rotors, and propellers. While traditional machining methods make it difficult to produce these parts accura

Spikes or roots are examples of disproportionate objects. VMC, with its automatic processing capabilities, can produce these parts that are difficult to produce using traditional methods.

Many standards govern how things in the military industry are designed and built. VMC’s accuracy and precision ensure the product is suitable for every application and industry.tely, multi-axis VMCs equipped with CNC machine tools can produce these parts quickly and efficiently.

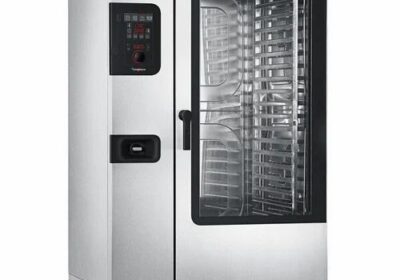

Overview

- Category: industrial , machinery

- Place with many folds

- Items with unusual shapes

- Parts from the military

Leave feedback about this